In today’s global trade environment of muted economic growth, rising costs, and supply chain disruptions, businesses are under pressure to find innovative ways to optimise imports. Even experienced supply chain managers face difficulties in identifying hidden inefficiencies that drive up costs.

We'll take a look at how an advanced import strategy can locate these bloated costs, including some techniques for saving money and enhancing efficiency with containerised imports. Beyond the basics, we’ll explore innovative ways you can transform your imports into a streamlined, competitive advantage.

“Businesses that have a good strategy in place for overall supply chain optimisations, beyond just the freight rate, are positioning themselves perfectly for a competitive advantage in the turbulent geopolitical climate.”

Liam Launders, Head of Sales, WTA

The importance of a thorough import strategy

A detailed import strategy goes beyond freight rate negotiation and quote requests to find cost savings. It looks at building supply chain resilience, and establishing competitive advantage.

- Cost Saving. Import costs can be unnecessarily high in a complex operation. A strategy helps to:

- Optimise freight routes and container utilisation.

- Minimise customs duties and ensure compliance.

- Reduce detention and demurrage charges.

- Make use of emerging technology.

- Supply Chain Resilience. Disruptions in global trade, such as port congestion or supplier delays, can cripple operations. A strategy assists with:

- Building contingency plans for unexpected disruptions.

- Maintaining inventory buffers to absorb delays.

- Competitive Advantage. Efficient import operations enable businesses to lower costs and improve delivery timelines, creating a stronger market position.

- By reducing lead times, you can respond faster to customer demands.

- With cost efficiency, you can offer more competitive pricing.

5 ways businesses waste money importing

Short-term planning

Failing to forecast future volumes and continually reacting to market volatility can leave shippers with bloated costs. Seasonal patterns in freight rates are well known.

Cost saving tip: Analyse past sales data to plan ahead and avoid periods of elevated rates as much as possible. Use knowledge of seasonal shipping patters to minimise shipping at these times of year.

Delays at customs

Our customs department will testify that incorrect or incomplete documentation is the biggest cause of import delays, and where there are delays, there are likely costs. Demurrage fees are usually anything between £60-£240 per day.

“Details or signatures missing, vague product descriptions, incorrect method for calculating the value of a shipment and confusion over incoterms are some of the most common causes of customs delays.”

Jamie Craig, Customs Specialist, WTA

Cost saving tip: Take the extra time required in advance to ensure the customs documentation is all in place before embarking on a shipment.

Bad container utilisation

Poorly planned shipping routes or underutilised containers can lead to unnecessarily inflated transportation costs. It’s unrealistic to achieve 100% container utilisation with every shipment, however, increases of 5-10% across every container could cut overall costs significantly.

Cost saving tip: Ensuring order sizes are aligned with container sizes as best as possible. A more technical solution could be in the form of advanced load-planning software, which can calculate with precision accuracy the best way to pack goods. There are many on the market, such as Cargo Planner, for a price which would be comfortably covered in savings if shipping reasonable volumes.

Poor choice of incoterms

Misallocation of incoterms can cause excessive costs or delays in a supply chain. For example, a supplier might try to be helpful by using DDP incoterms. However, without a UK entity, fulfilling the UK customs obligations would not be possible. Creating delays and bloated costs for both parties.

Cost saving tip: Engage properly with suppliers on the best incoterms and ensure these are properly reflected in the final price.

Lack of visibility

Without the deployment of a modern visibility tool, supply chain managers are working in the dark when it comes to import cost optimisation. Through these tools, you have complete transparency on where imports are costing more than necessary. Whether it’s particular routes, times of the year, ports or shipping lines.

Cost saving tip: Use a freight forwarder who provides a supply chain visibility tool as part of their service.

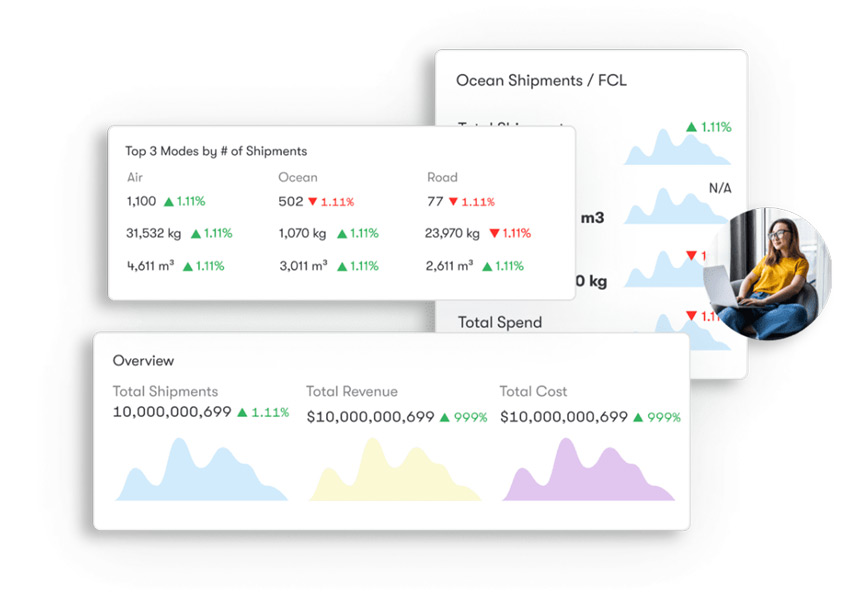

The WTA Platform

• Quickly find your shipments, with real-time status.

• Manage orders, invoices and shipments.

• Analyse and optimise your supply chain.

Vital sections of a winning import strategy

1. Executive SummaryThe executive summary provides an overview of the entire strategy. It highlights the document’s key objectives, such as cost reduction, compliance improvement, and better operational efficiency.

It should also briefly address the challenges the strategy aims to resolve and the expected outcomes. Including data-driven insights, such as the potential percentage reduction in shipping costs, strengthens the impact.

2. Cost Breakdown and AnalysisThis section provides a detailed breakdown of all current import costs, including freight charges, duties, and taxes. Build a complete picture of current supply chain import costs. Highlight areas targeted for savings.

3. Supplier and Vendor ManagementReliable suppliers are a vital part of import strategy. Outline the key performance priorities for suppliers, such as financial stability, delivery performance, and product quality. Outline a plan for regular supplier audits to ensure ongoing compliance with those KPIs.

4. Customs and Compliance StrategyThis section details how you will ensure compliance with international customs regulations, minimising the risk of delays or penalties. Provide detailed guidance on tariff classifications for your products, necessary documentation, and a duty reclamation processes.

5. Technology IntegrationOutline how digital tools, such as AI-driven forecasting platforms, can provide real-time visibility into the supply chain. Companies using AI effectively across their supply chain can see a 20% productivity boost and 30% reduction in operation costs, according to McKinsey research. Plan for how this can be implemented or improved upon with your imports.

6. Key Performance Indicators (KPIs)KPIs are essential for tracking the success of your import strategy. Set clear measurable goals related to total landed cost, customs clearance times, demurrage fees or any other statistic you deem vital.

7. Import Planning and Cost SavingDetail the optimal importing setup, including container utilisation strategies, preferred shipping routes, and modal choices. Include recommendations for cost saving, referencing the KPIs highlighted in the previous section.

8. Sustainability ConsiderationsAddress the environmental impact of the import process. State how the strategy is aligned with the company’s wider ESG strategy.

9. Action Plan and Implementation TimelineLay out a clear step-by-step implementation plan, assigning specific tasks and deadlines. Ensure accountability by identifying who is responsible for each step. Include regular milestones to assess progress, ensuring that the strategy remains on track.

A winning import strategy isn’t just a cost-saving measure, it’s critical for maintaining competitiveness with an increasingly complicated supply chain. By addressing inefficiencies, ensuring compliance, and leveraging advanced technology, businesses can find significant value in their import operations.

Take the time to review your current processes and assess areas for improvement. A well-crafted strategy tailored to your business can transform your operations, secure long-term benefits and competitive advantage.

If you’re looking for expert guidance, our team have decades of importing experience, from cost analysis to planning to technology implementation. Contact us today to learn how we can help streamline your imports and maximise your success.